Business

What You Need to Know About Retaining Walls

Gravity retaining walls are usually constructed from concrete blocks or concrete mass cast in place concrete. They are designed to resist the lateral earth pressures behind them. Gravity walls are designed for resistance to lateral earth pressures to prevent the wall’s overturning. The stability of a gravity wall is dependent on the weight of the wall and the weight of the soil pressures on the wall. The cross section of the wall is also affected by the weight and the size of the soil pressures.

Gravity retaining walls

Gravity walls are designed for resistance to back-fill soil pressure by retaining wall contractors adelaide. However, they can also resist higher lateral earth pressures at depth. To increase stability, a batter setback may be necessary. Stability can also be maintained by adjusting the geometry of gravity walls.

The cross section of gravity walls is usually trapezoidal. The wall’s base width is normally 50% of its total height. The amount of space between the wall and the wall can also affect the shape of the cross section. Depending on the application, the height of the wall can also vary. For example, a gravity wall may be 1.8 to 2.4 meters high. It may also be thicker at its base than at its height.

The cost of gravity retaining walls will vary depending on the materials used and how much reinforcement is used. If the wall is made from a mixture of bricks and mass concrete, it can be cost-effective to add reinforcement to the concrete. The wall must also be designed to resist other loads. These loads include passive soil pressure, vehicular loads, and reactive forces due to hydrostatic pressures at the water table.

A gravity retaining wall must have a reinforced mass large enough to withstand the pressures of the soil. The reinforced mass should be at least 60 percent as thick as the height of the wall. If the wall slope is significant, the reinforced mass may need to be greater. The wall must also be designed to overcome overturning forces.

The CSS algorithm calculates the optimal weight of gravity retaining walls. It is inspired by Coulomb’s and Gaus’ electrostatics in physics. It uses a set of problem parameters, such as the CP initial velocities, previous velocities, and the magnitude of the attracting force vector. It then initializes the CPs, and stores the best CPs. The algorithm then moves each CP toward others, considering the probability function.

The CSS algorithm can also help calculate the efficiency of gravity retaining walls. The CSS algorithm aims at moving each CP towards the others to achieve the optimum weight. The CSS algorithm consists of three levels: the initial velocities, the magnitude of the attracting force vector, and the probability function. The CSS algorithm then moves each CP toward the others considering the probability function.

Retaining walls made from sheet pile

Sheet pile retaining walls can be used to build permanent retail walls, quay walls, or coastal barriers. They are strong and can be easily installed in hard ground. They are also cost-effective, which reduces the overall project cost. Sheet pile retaining walls can also be used to build cofferdams or support below-grade parking structures. Sheet piles are also used in pump houses and to provide access to confined areas.

When designing sheet pile retaining walls, it is important to consider the difference in water pressure between the low and high sides of the wall. A difference in pressure can impact the wall’s stability and the integrity of the sealant. Sheet pile retaining walls are commonly used in axially loaded foundations, as well as coastal barriers and in railway embankments.

A sheet pile retaining wall is made up of individual steel sheet piles interlocked together. These piles are typically used to transfer pressure from the high side of the wall to the low side of the wall. They can also be used for changing the elevation of landscapes, landscaping ideas adelaide. Sheet pile walls can be installed into dense ground or into rock. They don’t require curing. Sheet pile walls can be installed quickly and without extensive preparation. Sheet pile walls can also be used to support excavations below-grade parking structures and in cofferdams.

A sheet pile retaining wall can be made up of single or multiple piles. The tensile strength of individual piles can be sufficient to resist the circumferential tension of a cellular wall due to the radial pressure of the fill. Sheet pile walls are also commonly used in combination with other elements. The load-bearing capacity of combined sheet piling walls is determined by the overall tensile strength of the individual piles. In addition, the load-bearing capacity of the secondary elements contributes less than five percent of the total load-bearing capacity of a combined sheet piling wall.

There are many types of sheet piles: face wall, intermediate and cellular. Each type of sheet piling has its own set of specifications. Section modulus for sheet piles made from grade 50 steel is approximately 50,000 ksi. This gives the sheet pile a design life of 120 year. For higher tensile strength, engineers may choose a higher grade of steel.

When using a combination of face and intermediate sheet piling, the wall has a higher section modulus than if it were made up of single or intermediate piles. In order to calculate the section modulus of a wall, engineers calculate the moment of inertia of the wall and then divide this number by the neutral axis. Engineers also calculate the lateral load of a wall and use this figure when designing the struts. Sheet pile retaining walls can also be built with stressed anchors. These anchors are connected to a curved tension face. They also provide additional lateral retaining power.

Business

Amazon Courtesy Credit: Understanding and Utilizing It

Amazon courtesy credit, the e-commerce giant, is known for its customer-centric approach and commitment to ensuring a satisfactory shopping experience for its users. One of the ways Amazon achieves this is through its CC policy, aimed at compensating customers for certain inconveniences or issues encountered during their shopping journey.

What is Amazon Courtesy Credit?

Amazon Courtesy Credit (ACC) is a form of compensation provided to customers in recognition of various issues or inconveniences they may experience while shopping on the platform. It serves as a gesture of goodwill from Amazon to maintain customer satisfaction and loyalty.

Instances Eligible for Amazon Courtesy Credit

Late Deliveries

Customers may be eligible for ACC if their orders are delivered later than the estimated delivery date provided at the time of purchase.

Damaged or Defective Items

In cases where items arrive damaged or defective, customers can request ACC as a form of compensation for the inconvenience caused.

Inaccurate Product Descriptions

If customers receive items that do not match the product descriptions or specifications listed on the this website, they may qualify for ACC.

How to Request Amazon Courtesy Credit

Customers can request ACC by contacting Amazon customer support and providing details about the issue they encountered. Amazon representatives will assess the situation and determine if compensation is warranted.

Factors Affecting Amazon Courtesy Credit

Customer History and Engagement

Amazon may take into account a customer’s purchase history, order frequency, and overall engagement with the platform when determining eligibility for ACC.

Order Frequency

Frequent and loyal Amazon customers may receive more favorable consideration for courtesy credit compared to occasional shoppers.

Issue Severity

The severity and impact of the issue experienced by the customer also play a role in determining the amount of CC provided.

Benefits of Amazon Courtesy Credit

Amazon Courtesy Credit offers several benefits to customers, including:

- Compensation for inconvenience or dissatisfaction with the shopping experience.

- Enhanced customer satisfaction and loyalty.

- Reinforcement of Amazon’s commitment to customer service excellence.

Limitations and Considerations

While Amazon Courtesy Credit can help address certain issues encountered by customers, it’s important to note that it may not fully compensate for all inconveniences or dissatisfaction experienced during the shopping process.

Customer Experiences and Feedback

Many Amazon customers have shared their experiences and feedback regarding Amazon Courtesy Credit on various online platforms and forums. Exploring these insights can provide valuable perspectives and tips for navigating the process of requesting and utilizing courtesy credit.

Conclusion

It serves as a valuable tool for maintaining customer satisfaction and loyalty by compensating users for certain issues or inconveniences encountered during their shopping experience. By understanding the eligibility criteria and process for requesting courtesy credit, customers can leverage this benefit to enhance their overall shopping experience on Amazon.

FAQs

How do I request ACC for a late delivery?

- To request it for a late delivery, you can contact Amazon customer support through their website or app. Provide details about your order, including the order number and the estimated delivery date. Amazon representatives will assess the situation and may offer compensation in the form of CC.

What should I do if I receive a damaged or defective item from Amazon?

- If you receive a damaged or defective item from Amazon, you should contact Amazon customer support immediately to report the issue. Provide relevant details such as the order number, item description, and images showing the damage or defect. Amazon will assist you in resolving the issue and may offer CC as compensation.

Is ACC provided automatically, or do I need to request it?

- ACC is not provided automatically. You need to request it by contacting Amazon customer support and explaining the issue you encountered. Amazon representatives will evaluate your request and determine if CC is warranted based on their policies and guidelines.

Can I use ACC for future purchases on the platform?

- Yes, ACC can typically be used for future purchases on the Amazon platform. Once credited to your account, CC can be applied towards the payment of eligible items during checkout. However, it’s essential to check the terms and conditions associated with the Courtesy Credit for any specific limitations or restrictions.

Are there any restrictions or limitations on the use of ACC?

- While It can generally be used for purchases on the platform, there may be certain restrictions or limitations depending on the terms and conditions associated with the credit. For example, Courtesy Credit may have an expiration date or be limited to specific categories of products. It’s advisable to review the terms carefully to understand any restrictions before using the Courtesy Credit.

Business

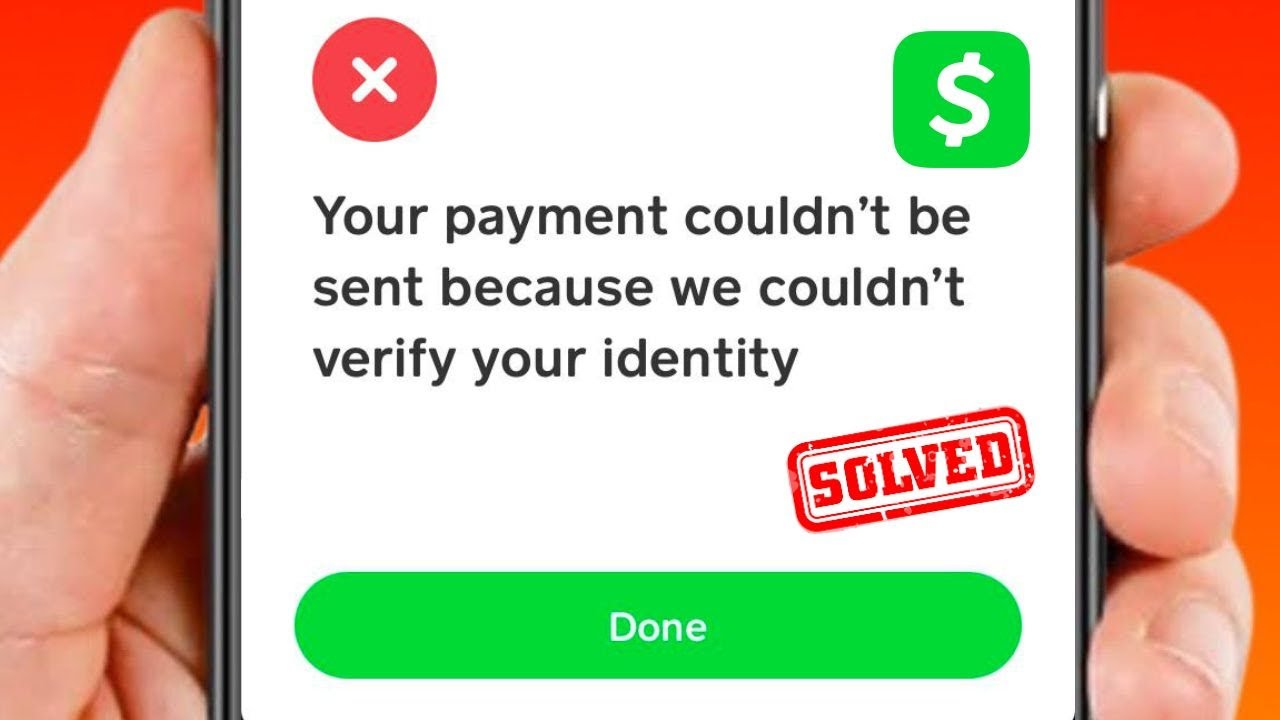

Your Payment Could Not Be Sent on Cash App: Understanding and Resolving Issues

The article “your payment could not be sent cash app” This app emerged as one of the leading mobile payment platforms, offering users a convenient way to send, receive, and manage money directly from their smartphones. While Cash App provides a seamless payment experience for millions of users, occasional issues may arise, leading to payment failures and frustrations for users.

Understanding Payment Issues on Cash App

Payment issues on Cash App can occur due to various reasons, ranging from technical glitches to user error. When your payment cannot be sent on Cash App, it’s essential to understand the underlying causes and take appropriate steps to resolve the issue promptly.

Common Reasons for Payment Failures

Several factors can contribute to payment failures on Cash App, including insufficient funds, incorrect recipient information, network connectivity issues, and security concerns. Identifying the specific reason for the payment failure is crucial for resolving the issue effectively.

Steps to Take When Your Payment Cannot be Sent

If your payment could not be sent on Cash App, consider the following steps to troubleshoot the issue:

Check Account Balance:

- Ensure that you have sufficient funds in your Cash App account to cover the payment amount.

Verify Recipient Information:

- Double-check the recipient’s details, including their Cash App username or phone number, to ensure accuracy.

Retry the Payment:

- Attempt to resend the payment after confirming that all details are correct.

Monitor Transaction Status:

- Keep track of the transaction status within the Cash App interface to receive real-time updates on the payment attempt.

Contact Cash App Support:

- If the issue persists, reach out to Cash App support for assistance and further troubleshooting steps.

Contacting Cash App Support

In case of persistent payment issues, contacting Cash App support is the best course of action. Users can reach out to Cash App customer service through the app or website for personalized assistance and resolution of payment-related concerns.

Tips to Avoid Payment Issues on Cash App

To minimize the risk of payment failures and ensure a smooth transaction experience on Cash App, consider the following tips:

- Maintain Sufficient Funds: Regularly check your Cash App balance and add funds as needed to avoid payment failures due to insufficient funds.

- Verify Recipient Details: Always double-check the recipient’s information before initiating a payment to prevent errors and potential delays.

- Stay Updated: Keep your Cash App and device software up to date to benefit from the latest security patches and enhancements.

- Use Secure Networks: Avoid conducting Cash App transactions over unsecured or public Wi-Fi networks to protect your sensitive information from potential security threats.

Ensuring Account Security

In addition to addressing payment issues, prioritizing account security is paramount when using Cash App. Users should enable two-factor authentication, review transaction history regularly, and report any unauthorized activity promptly to safeguard their accounts and financial information.

Comparing Cash App with Other Payment Platforms

While Cash App offers convenience and flexibility for peer-to-peer payments, it’s essential to compare its features and functionality with other payment platforms. By evaluating factors such as transaction fees, security measures, and user experience, users can make informed decisions about which platform best suits their needs.

Conclusion

In conclusion, encountering payment issues on Cash App can be frustrating, but understanding the underlying causes and taking proactive steps can help resolve the problem effectively. By following best practices for account security, verifying recipient information, and staying informed about transaction status, users can minimize the risk of payment failures and enjoy a seamless payment experience on Cash App.

FAQs

What should I do if my payment fails on Cash App?

- If your payment fails on Cash App, double-check the recipient’s information and account balance before attempting to resend the payment. If the issue persists, contact Cash App support for assistance.

How long does it take for Cash App to resolve payment issues?

- The time taken to resolve payment issues on Cash App varies depending on the nature of the problem. In most cases, Cash App strives to address payment concerns promptly and efficiently.

Can I cancel a failed payment on Cash App?

- Yes, users have the option to cancel a failed payment on Cash App before it is successfully processed. However, once a payment is completed, it cannot be canceled or reversed.

Does Cash App charge a fee for failed payments?

- Cash App does not charge a fee for failed payments. However, standard transaction fees may apply when sending money or using certain features within the app.

Are there any limits on the amount of money I can send through Cash App?

- Cash App imposes certain limits on the amount of money users can send and receive within a specified time frame. These limits may vary based on account verification status and other factors.

Business

Ace Hair Extensions & Co Overtakes other beauty brands with it’s new Serum & XL Ace Lace Glue

A brand receiving strong demands for its services must always continue to listen to their customers on what better ways to serve them, which Ace Hair Extensions & Co did last year which led to the innovations of new skus and items.

They have continued to defie luxury downturn and have continued to see new customer satisfactory reviews on forums and social media blogs alike.

Besides their Glue being #1 on the market for bonding strength, The Parfum Serum is made with different plant and root extracts, revealing natural scents and tones that last all day.

It’s Non oily, very silk-like, smells amazing, and is made from organic properties.

Many owning these beautiful products know how much they mean to Ace Hair Extensions & Co when they receive their packages in the mail and see the stylish packaging and attention to detail so they dress their bathroom counters and dressing tables up with their new luxuries.

Experience greatness again https://acehairextensionsco.com/products/hair-serum?variant=40613161369661

Others10 months ago

Others10 months agoDavid T Bolno: Why Giving Back To The Community Is So Crucial

Travel10 months ago

Travel10 months agoPractical And Essential Car Interior Accessories To Add Comfort And Convenience To Your Drive

Travel10 months ago

Travel10 months agoBusiness Visa for CANADA

Business10 months ago

Business10 months agoTop Reasons Why you Need to Consider Outsourcing Real Estate Photo Editing

Health10 months ago

Health10 months agoGarlic Is The Best Vegetable To Treat Heart Problems

Business10 months ago

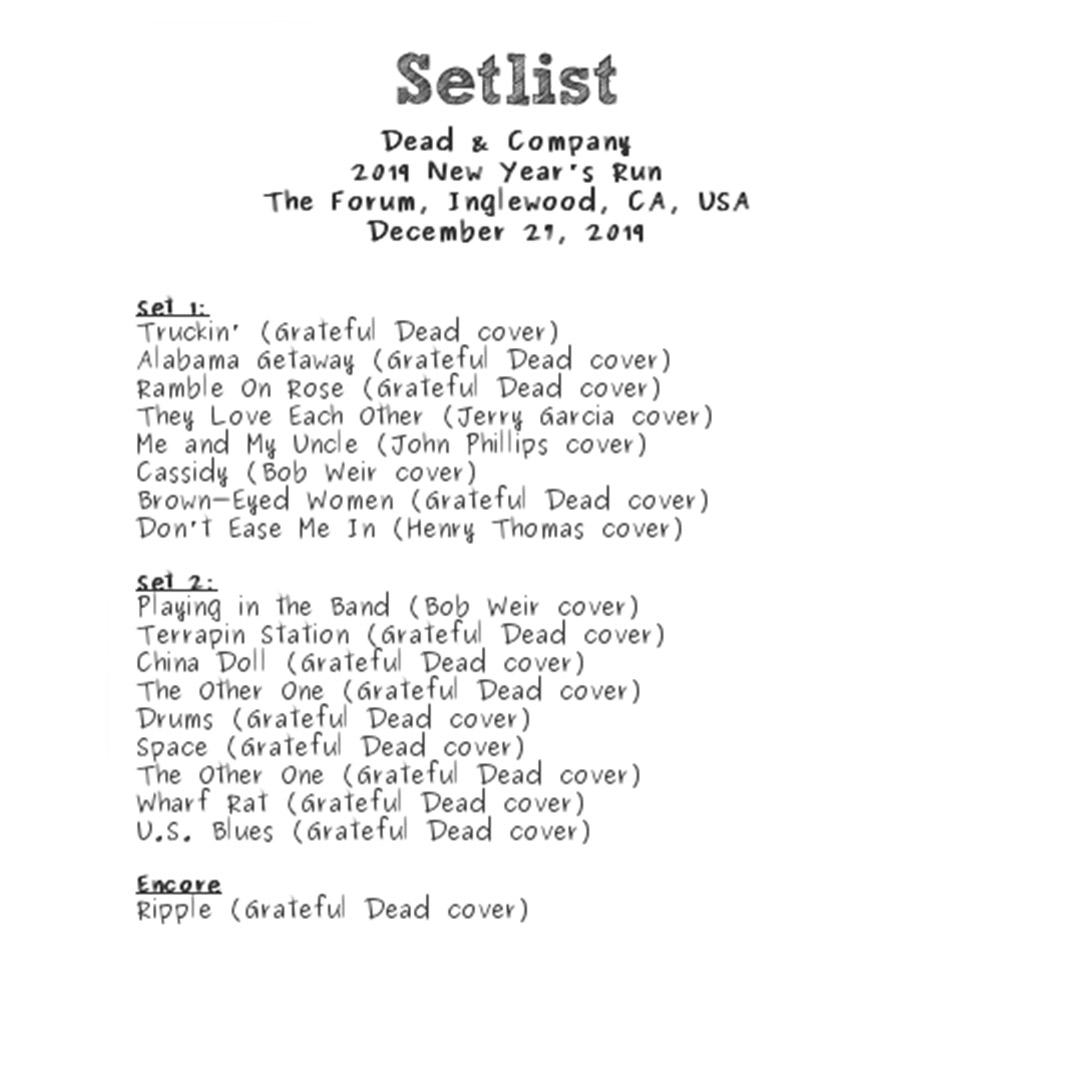

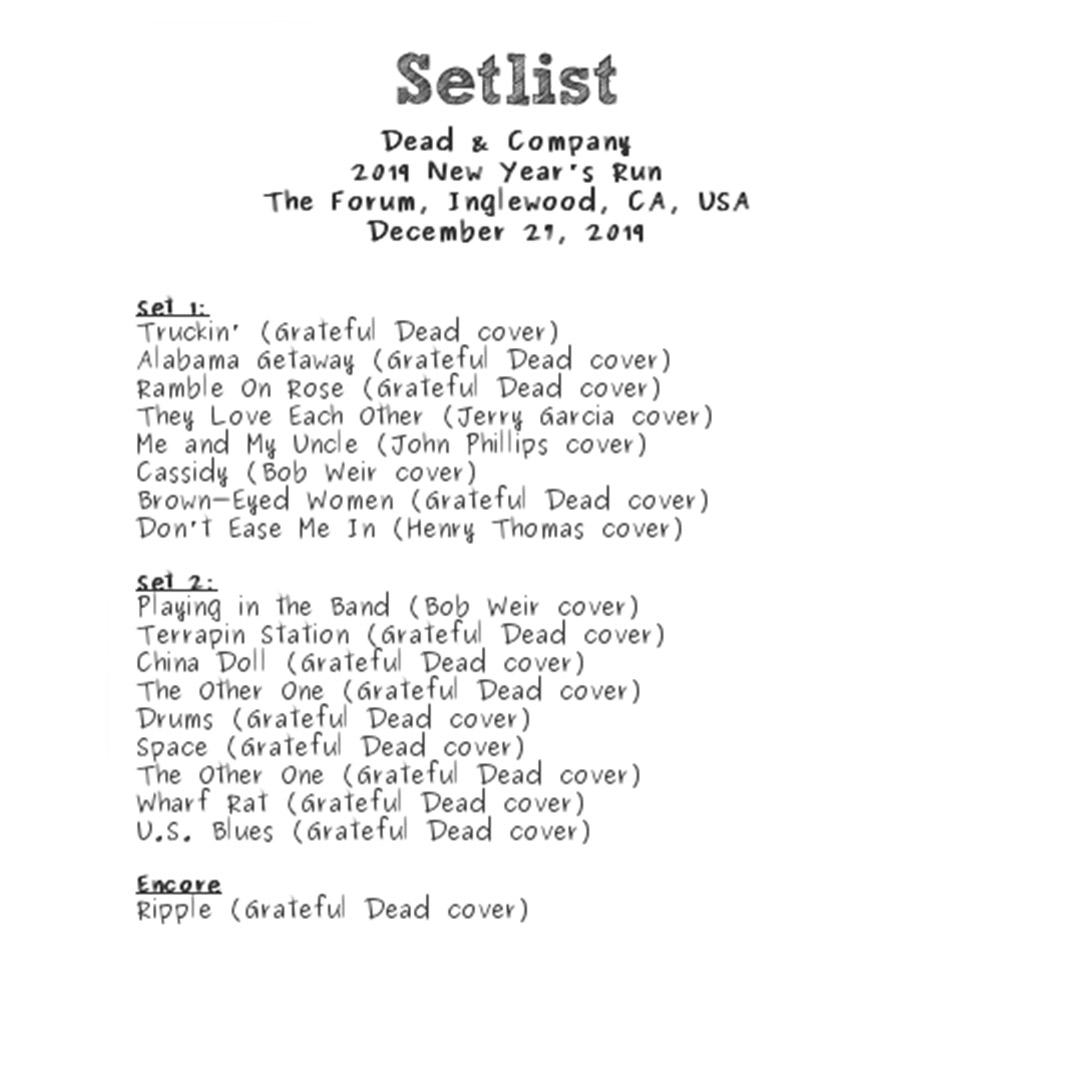

Business10 months agoDead And Co Setlist What They Played At The Gorge Amphitheatre

Fashion10 months ago

Fashion10 months agoTips For Choosing The Right For Engagement Diamond Rings

Tech10 months ago

Tech10 months agoThe Best Way to Never Get Lost: Buy Wayfinding Signs!