Tech

EV Charging: What to Do After Buying an Electric Car

You probably have a few questions if you’ve just bought an electric car. One is, “What is EV charging?” Like any chargeable device or electronic, electric vehicles and plug-in hybrid electric vehicles need an EV charger to maintain a full battery. Charging can be done at home with a standard 220V cord, wall box, or public EV chargers. The latter is faster but can be expensive.

How It Works

EV Charging charges an electric vehicle’s battery using EV charging equipment, also known as EVSE (Electric Vehicle Supply Equipment). It uses electricity to power the EV’s batteries and can be done at home, in a public charger, or even at work.

The most common way to charge an EV is at a Level 2 public charging station, which can power a car for several hours. It is a great way to top up your EV before heading out on the road, but if you need a faster recharge, consider a Level 3 DC fast charger.

You can find these EV charging stations on highways, hotels, airports, shopping centers, and some reputable industry experts like Delta Electronics.

Most charging stations charge by kilowatt-hours, a standard pricing model in the United States. You can expect to pay about 16 cents per kWh at most public charging stations, though this depends on the EV type you drive.

You can find public EV charging stations using smartphone apps or websites; many will let you know whether or not the plugs are in use. You can save time and aggravation by avoiding looking for the charging station yourself.

What You’ll Need

Electric vehicles (EVs) offer many advantages over gasoline-powered cars, including a lower maintenance cost and a superior driving experience. However, one of the most confusing aspects of getting an EV is how to charge it. Depending on your vehicle, you may have a choice of charging equipment to install in your home or garage. There are two main types: Level 1 and Level 2.

Level 1 EVSE (Electric Vehicle Supply Equipment) operates on 120 volts, like a standard household outlet. It provides about 5 miles of range per hour of charging.

For a faster charging session, consider installing a Level 2 EVSE. These units operate on 240 volts, typically providing about 15 to 40 miles of range per hour of charging.

You can also find intelligent chargers with Wi-Fi connectivity that allow you to monitor and control your charging through an app. These are more expensive than non-smart models, but they can be beneficial for tracking your energy costs, managing your charging schedule, and making payments.

There are also fast DC fast charging stations available at public locations that can top up your EV battery in 30 minutes or less. These are usually a higher price than Level 2 and Level 3 chargers, but they can be helpful if you live in an area with frequent heavy traffic.

Where to Charge

When it comes to charging EVs, there are multiple ways to do so. One way is to find a public charging station to plug in for a quick charge. They’re usually found in parking garages, workplaces and commercial lots and are available for free or a small fee.

Another option is installing a level 2 charging unit in your home. These come in various styles and can be purchased online from home-improvement stores. They typically cost around $500 to $700, and you’ll need an electrician to install them.

The good news is that many cities and states are developing EV charging infrastructure, so there are plenty of places where you can charge up. These include shopping malls, airports, grocery stores and even some fast-food chains. It’s essential to remember that not all EVs are compatible with all charging stations. Some models have a unique plug that may not be compatible with all the chargers on the market.

Costs

The cost to charge your electric vehicle can vary from state to state and even within the same state. The amount you’ll pay for electricity depends on your location, the type of charger, and your local energy provider’s rates.

Using an EV during off-peak hours can be a great way to save money, as many utility providers offer lower prices at certain times. It is beneficial for drivers who want to minimize their carbon footprint.

Public charging stations are becoming more common, so they’re also an excellent option to help you charge your vehicle. They typically come with dedicated apps that make it easy to use and pay for your charges.

In addition, several incentives can reduce your overall EV charging costs. These include federal, state, and local programs that provide monetary and tax credits.

Aside from these programs, it’s worth considering how you drive and what kind of vehicle you own before deciding on EV charging. EVs are cheaper than gas-powered vehicles and offer several benefits, including low fuel costs, quiet engines, and no tailpipe emissions.

Tech

Modern AI Navigation: 3 innovative options for use

Machine learning and deep learning are integral to various industries. Ground transportation systems leverage predictive algorithms to optimize travel flows, forecast congestion, and enhance fuel efficiency. Now, these advancements are taking flight.

Significant strides in AI navigation are transitioning from research labs to mainstream applications, offering aeronautics enhanced reliability, safety, and efficiency.

AI-Powered Inertial Navigation for UAVs in GPS-Compromised Environments

In many UAV operations, GPS signals are crucial. However, these signals can be disrupted during natural disasters or military operations. Bavovna.ai, a graduate of the US Air Force Labs Mass Challenge acceleration program, is pioneering an AI-driven PNT navigation system for aerial, surface, and subsurface vehicles.

Dual-Use AI Navigation for UAV Drones

Bavovna’s inertial navigation system, designed for dual use, utilizes sensor fusion and pre-trained ML/DL algorithms to enable autonomous operations. With robust core electronics, the system withstands common electromagnetic warfare threats. It’s also a low-SWaP (Size, Weight, and Power) solution, making it ideal for UAV models and Class II aerial vehicles.

In trials, the Aurelia X6 Max multicopter operated autonomously without remote control, GPS, or other communications, gathered location intelligence, and returned to its starting point. Bavovna’s AI navigation system aims for a positioning error margin of just 0.5%, even on complex routes up to 30 miles (48 km). The team is expanding its use cases to include Signals Intelligence, mine detection, automatic target engagement, and security surveillance.

AI Copilots for Commercial Aviation

Modern aircraft are equipped with sophisticated autopilot systems to assist pilots in controlling altitude, course, thrust, and navigation. However, pilots can be overwhelmed by the numerous alerts and system interfaces demanding their attention. NASA estimates that pilots are distracted by 34 different activities, from communication to scanning for visual meteorological conditions (VMC) traffic, which can lead to human errors and potential dangers.

AI Airflow Traffic Management

The Air-Guardian project by MIT’s CSAIL seeks to improve the human-machine interface (HMI) of existing autopilot systems for safer operations. The AI system uses eye-tracking to detect pilot distraction and “saliency maps” to understand aircraft behavior.

Based on a continuous-depth neural network model, the copilot system can identify early risk signs and take control when necessary. During trials, the Air Guardian system reduced flight risks and improved navigation success.

Advanced Airflow Traffic Management to Alleviate Congestion

Unpredictable events like adverse weather can significantly impact air traffic, causing congestion in specific airspace sectors. This congestion affects all network participants, resulting in a cascade of delayed flights.

Co-funded by the European Union and led by Universita Ta Malta, the ASTRA project aims to predict air traffic congestion one hour in advance and suggest optimal paths for traffic controllers. The project, which stands for AI-enabled Tactical FMP Hotspot Prediction and Resolution, trains its prediction algorithm on historical data from EUROCONTROL (from 2019 onwards). The AI system provides prescriptive scenarios to optimize flow management positions, ensuring safety, efficiency, reduced fuel consumption, and minimal environmental impact.

AI holds immense potential in airborne navigation, and we anticipate further innovations in sensor fusion, AI-powered PNT, and aerial traffic management in the coming years.

Tech

Boost Your Telegram Channel Promotion with KYG’s Services

Telegram channels are powerful tools for businesses aiming to enhance brand awareness, share valuable content, build active communities, improve customer relationships, and boost sales. However, effective telegram promotion and management requires strategic efforts. This article explores how KYG’s services can support your Telegram channel promotion, leveraging advanced tools and strategies to maximize engagement and growth.

Services for Telegram Channel Promotion

Creating engaging content is critical for any social media platform. On Telegram, diverse content types such as text, media, and polls can captivate your audience. KYG’s services can assist in developing a content strategy that resonates with your target audience. With tools to set clear objectives and KPIs, KYG ensures you monitor key metrics and adjust your strategy based on performance and feedback.

Cross-Promotion Tactics

Expanding your reach through cross-promotion is vital. KYG supports cross-promotion efforts by providing insights into the most effective platforms for your audience. Whether you’re leveraging other social media channels or partnering with similar communities, KYG’s analytics help identify and optimize these opportunities, ensuring you attract engaged and interested users.

Influencer Partnerships

Influencer marketing is indispensable for boosting engagement and communication. KYG’s platform aids in identifying influencers who align with your brand values and target audience. By facilitating clear collaboration proposals and tracking campaign results, KYG ensures that your influencer partnerships are both effective and measurable, driving more users to your Telegram channel.

Exclusive Offers and Contests

Offering exclusive content and running contests are proven methods to boost engagement. KYG can streamline the process of advertising these offers across various platforms, ensuring maximum visibility. Additionally, KYG’s analytics tools help monitor the effectiveness of these campaigns, providing valuable insights for future strategies.

Consistent Communication and Engagement

Maintaining an active community requires consistent engagement. KYG’s community management tools make it easier to plan and track communication efforts. By providing comprehensive analytics and personalized recommendations, KYG helps ensure that your Telegram channel remains vibrant and engaging. Responding to comments, rewarding active members, and monitoring community health are all simplified with KYG.

Why Choose Know Your Group

KYG offers a comprehensive suite of tools and services designed to support effective Telegram channel promotion. With KYG, you get:

- Advanced Analytics: Monitor engagement, growth, and performance with precision.

- Customizable Community Portals: Tailor your community space to reflect your brand’s identity.

- Streamlined Onboarding: Easily integrate new members into your community.

- Monetization Tools: Turn your engagement into revenue with various monetization strategies.

- Expert Support: Benefit from personalized recommendations and strategic growth insights.

Know Your Group ensures your Telegram channel thrives, driving engagement and achieving your business goals.

FAQs

What is the best way to create engaging content for a Telegram channel?

Utilize diverse content types like text, media, and polls, and tailor your content to your audience’s interests and needs. KYG’s tools can help set clear objectives and track content performance to make necessary adjustments.

How can KYG help maintain consistent communication on Telegram?

KYG’s tools streamline communication planning and tracking, making it easier to engage with your community regularly. Their analytics provide insights to improve engagement strategies continuously.

What makes KYG a good choice for Telegram channel promotion?

KYG offers a comprehensive suite of tools for community management, including content strategy, cross-promotion, influencer partnerships, and engagement tracking, all tailored to help your Telegram channel succeed.

Tech

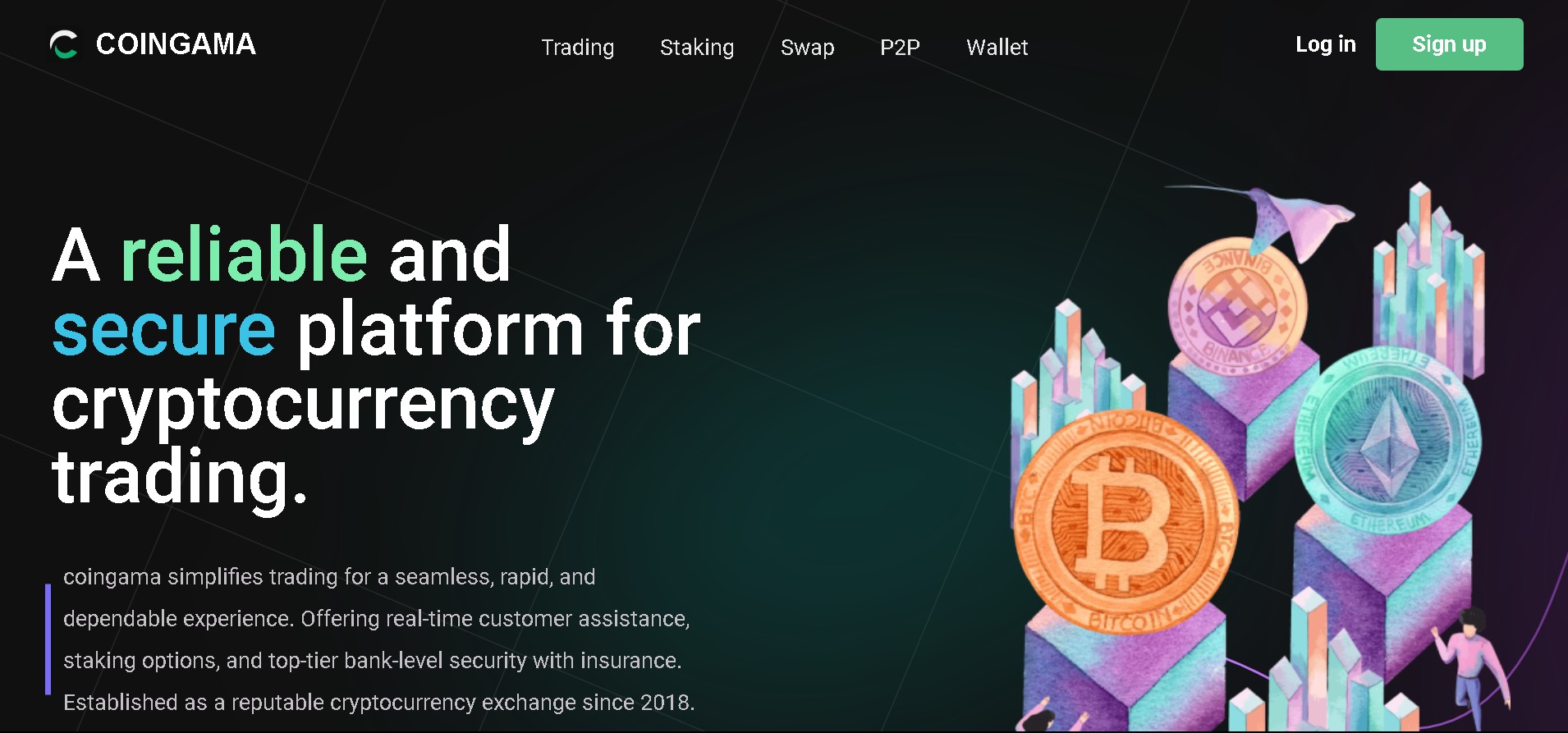

Coingama Exchange Review

Coingama is emerging as a premier cryptocurrency exchange platform, designed to cater to both beginner and seasoned traders. With its user-friendly interface, advanced security measures, and comprehensive trading tools, Coingama aims to provide a seamless and secure trading experience. This review delves into the various features and benefits that make Coingama a standout choice in the crowded cryptocurrency exchange market.

User Experience: One of the defining features of Coingama is its intuitive and easy-to-navigate interface. The platform is designed with user experience in mind, making it accessible even for those new to cryptocurrency trading. The registration process is streamlined, allowing users to set up their accounts quickly and start trading without unnecessary delays. The dashboard is well-organized, providing users with all the necessary tools and information at their fingertips. Additionally, Coingama offers a mobile application, enabling users to trade on-the-go with the same level of efficiency and security as the desktop version.

Security Measures: Security is a paramount concern for any cryptocurrency exchange, and Coingama excels in this area. The platform employs a range of advanced security measures to protect users’ funds and personal information. These include two-factor authentication (2FA), encryption, and the use of cold storage for the majority of users’ assets, which significantly reduces the risk of hacking. Coingama also conducts regular security audits and updates to ensure that its security protocols remain robust and up-to-date. Users can trade with confidence, knowing that their assets are safeguarded by some of the most advanced security measures in the industry.

Trading Features and Tools: Coingama offers a comprehensive suite of trading features that cater to a wide range of traders. The platform supports numerous trading pairs, including major cryptocurrencies such as Bitcoin, Ethereum, and Litecoin, as well as various altcoins. This wide selection allows traders to diversify their portfolios and take advantage of different market opportunities. Coingama also provides advanced trading tools, including real-time charts, technical indicators, and market analysis, which help users make informed trading decisions. The platform’s trading engine is designed for high performance, ensuring fast and reliable execution of trades even during periods of high market volatility.

Liquidity and Fees: Liquidity is a crucial factor for any exchange, and Coingama ensures ample liquidity across all trading pairs, allowing for smooth and efficient trading. The platform has partnered with several liquidity providers to maintain tight spreads and minimize slippage. When it comes to fees, Coingama is competitive, offering a transparent fee structure with no hidden charges. Trading fees are kept low to attract more users, and there are various incentives and promotions available that further reduce the cost of trading on the platform.

Customer Support: Reliable customer support is essential for any trading platform, and https://coingama.com/ excels in this area as well. The exchange offers 24/7 customer support through multiple channels, including live chat, email, and a comprehensive FAQ section. The support team is responsive, knowledgeable, and dedicated to resolving any issues that users may encounter. This level of support ensures that users can trade with confidence, knowing that assistance is readily available whenever needed.

Educational Resources: Understanding the importance of education in trading, Coingama provides a wealth of educational resources for its users. The platform offers tutorials, webinars, and articles that cover various aspects of cryptocurrency trading, from basic concepts to advanced strategies. These resources are designed to help traders enhance their knowledge and improve their trading skills, making Coingama an excellent choice for both learning and trading.

Conclusion: In conclusion, Coingama is a reliable and efficient cryptocurrency exchange that offers a comprehensive trading environment. Its user-friendly interface, robust security measures, advanced trading tools, ample liquidity, competitive fees, and excellent customer support make it an attractive option for traders of all levels. Whether you are just starting out in the world of cryptocurrency trading or are an experienced trader looking for a dependable platform, Coingama provides the features and support needed to succeed. With its commitment to security, innovation, and user satisfaction, Coingama is well-positioned to become a leading player in the cryptocurrency exchange market.

Others10 months ago

Others10 months agoDavid T Bolno: Why Giving Back To The Community Is So Crucial

Travel10 months ago

Travel10 months agoPractical And Essential Car Interior Accessories To Add Comfort And Convenience To Your Drive

Travel10 months ago

Travel10 months agoBusiness Visa for CANADA

Business10 months ago

Business10 months agoTop Reasons Why you Need to Consider Outsourcing Real Estate Photo Editing

Health10 months ago

Health10 months agoGarlic Is The Best Vegetable To Treat Heart Problems

Fashion10 months ago

Fashion10 months agoTips For Choosing The Right For Engagement Diamond Rings

Business10 months ago

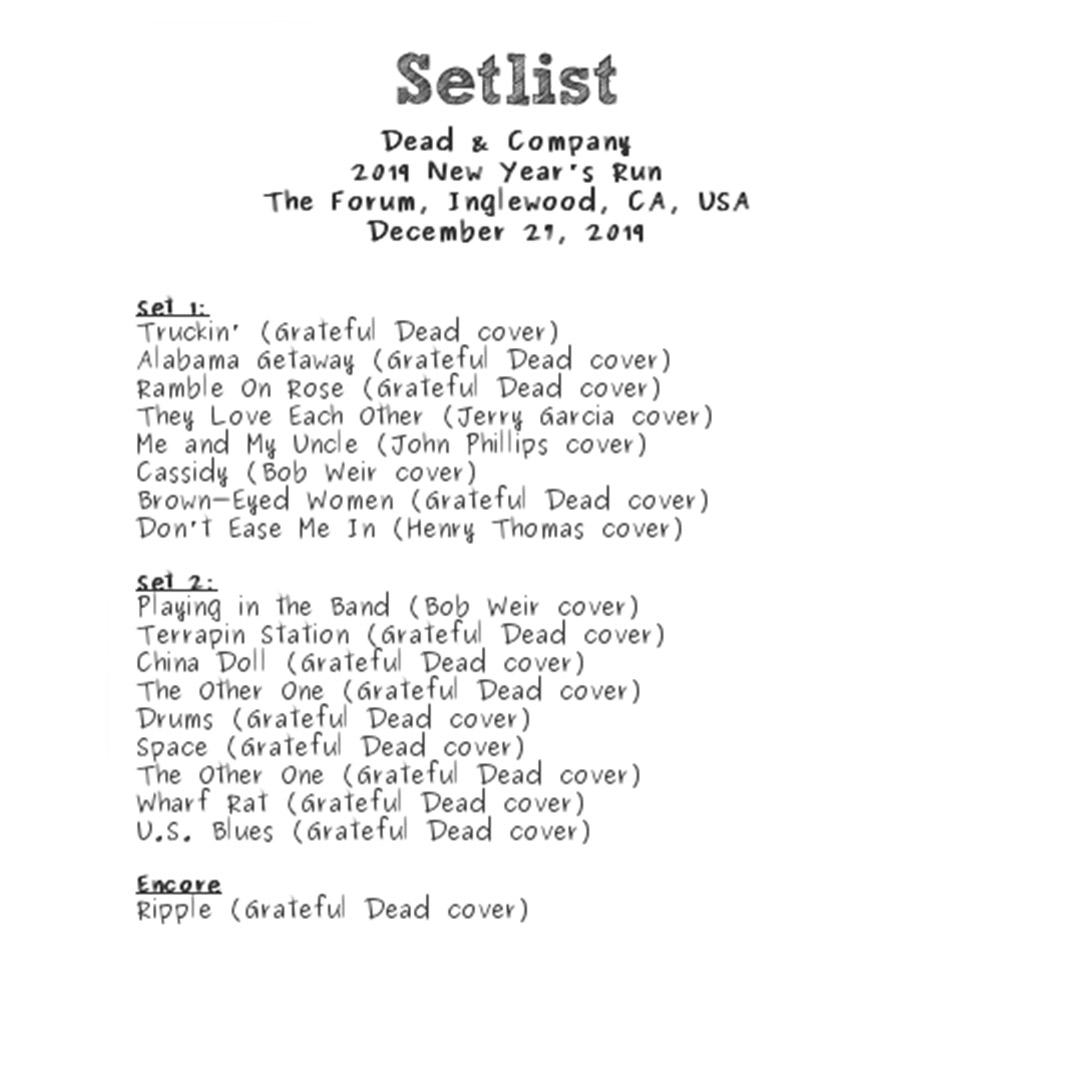

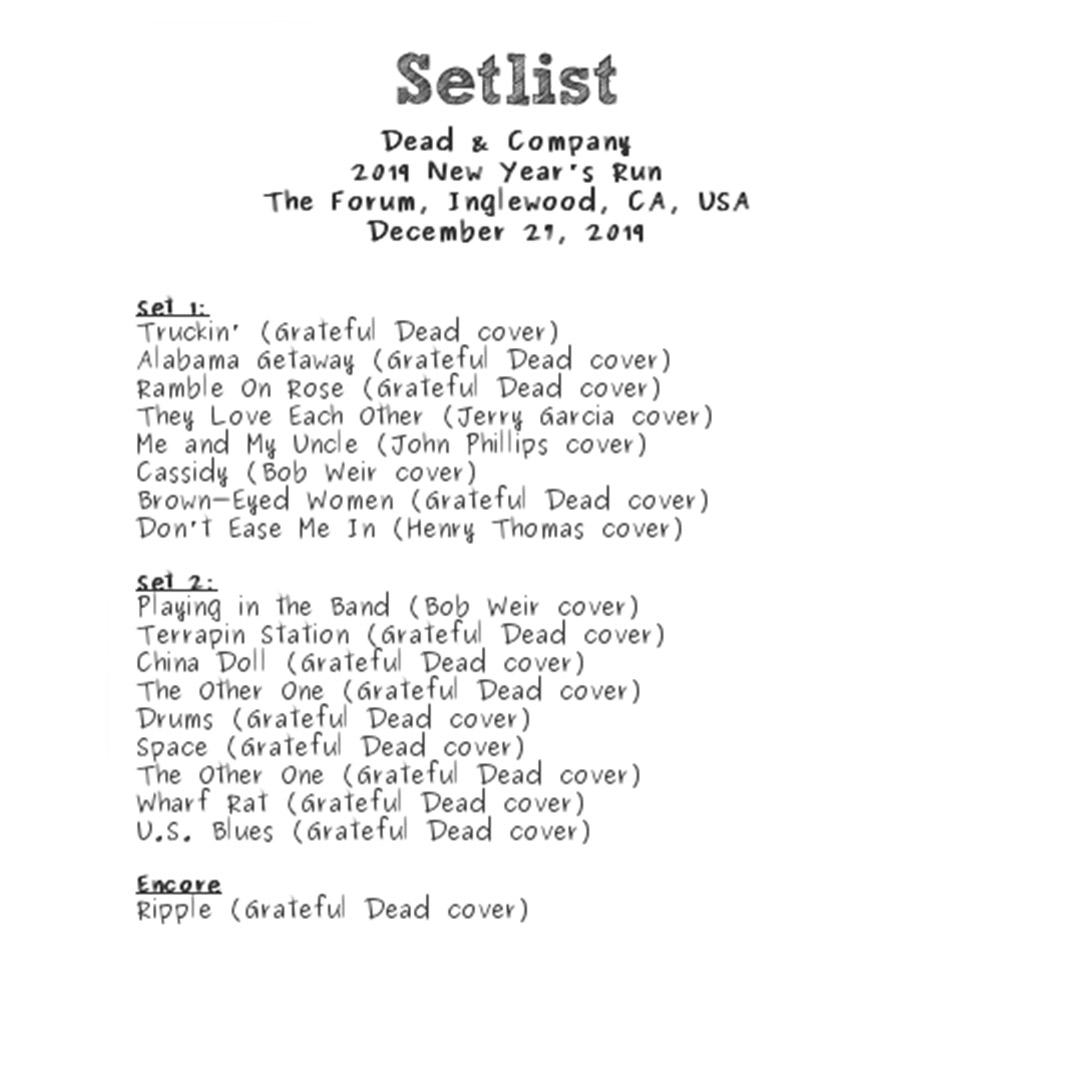

Business10 months agoDead And Co Setlist What They Played At The Gorge Amphitheatre

Tech10 months ago

Tech10 months agoThe Best Way to Never Get Lost: Buy Wayfinding Signs!